One of the main issues of the supply chain management is achieving the maximum and optimal level of efficiency in terms of time of delivery. The problem is complicated by the need for consideration of trade regulations, policies, and relationship dynamics between two economic sectors. The given analysis is primarily focused on semiconductor delivery between United States and China, where shortening delivery time can be categorized as the most viable and effective solution. The reasons include resilience under crisis, more robust management, and minimal resource waste. However, pressure from the suitability and geopolitical standpoint further complicate the supply chain modification process.

Logistics and Supply Chain

It is important to note that logistics and supply chains are critical aspects of all economic and business activities. The given assessment will primarily focus on the semiconductor industry supply chain networks effectiveness between China and the United States trade systems. The core elements of the analysis are centered around the approach, which views the shortening of the delivery chain as the main measure to ensure the most optimal and effective delivery time. The given topic is especially critical due to the current COVID-19 global crisis, which heavily impacted the regulations associated with supply chain and logistics management. Therefore, the analysis will also review and address various aspects of global supply chain networks under a crisis. In addition, a general overview of the subject is of paramount importance in order to provide an in-depth understanding and insight into the given complex subject. Thesis: Shortening the delivery chain is the most effective and optimal way to shorten the delivery time in the semiconductor industry affected by the COVID-19 global crisis as it allows businesses to stock semiconductors, comply with US regulations regarding Chinese manufacturers, and does not change the transport means used.

Literature Review

In order to properly understand the critical importance as well as associated benefits of delivery chain shortening, especially during times of crisis, it is necessary to consult the current literature on the subject. The current state of logistics and supply chain management no longer resembles its previous formats. There are a number of reasons, which primarily include a shift in priorities and technological developments. For example, the key business concept in supply chain is sustainability and the latter’s performance is becoming more relevant in logistics, which involves “the factors influencing the adoption of environmental sustainability initiatives, the customer perspective in the sustainable supply chain, and the information and communication technologies supporting green initiatives” (Centobelli et al., 2017, p. 454). Considering the fact that transportation is a cornerstone of delivery mechanisms, the pressures on carbon emission minimizations and energy regulations are also impacting the sector, which makes the search for an effective solution even more important (Gracht & Darkow, 2016). In the case of technological advancements, instruments, such as blockchain technologies, are increasingly utilized in order to achieve the highest levels of efficiency and effectiveness of supply chain management (Choi et al., 2020). In other words, supply chain management is constantly evolving and undergoing novel pressure types associated with national and global regulations.

Addressing the stated problems and issues requires a precise and calculated effort in order to identify the key points of adjustments. One of the main supply chain business concepts is operational research or OR, which focuses on supply chain optimization and trend determination (Speranza, 2018). In addition, one can also utilize the critical key performance indicators, such as perfect order rate or POR. POR “is composed of sub-measures touching technical, economic, quality and safety aspects of logistics processes. POR directly defines what the organization considers to be the perfect implementation of its tasks” (Jacyna-Gołda et al., 2019, p. 25). All of these methodological frameworks are designed to improve efficiency, which, currently, is focused on delivery time shortening. It is stated that “the current trend in logistics and the distribution chain is the pressure to reduce the delivery time, which was triggered by the e-commerce trend. In order to shorten the delivery time, it is necessary to choose the location of the warehouse or distribution center to maximize efficiency” (Kudláčková & Chocholáč, 2017, p. 1). In other words, the location-related factors, as well as modes and patterns of transportation, play a critical role in achieving the necessary efficiency from delivery time shortening. Such efforts require some level of automation as well as computerization of essential tasks of control and pattern setting (Stopka, 2017, p. 267). The given literature clearly indicates that delivery time shortening is the current trend and a top priority in order to achieve a high level of efficiency in supply chain management.

In addition to shortening the supply chain, there is another commonly practiced method to reduce delivery time and prevent delays, and this is to change the means of transportation. However, the new COVID-19 related regulations and the existing ones, specifically those about environment protection, make it unprofitable and difficult for firms to choose and adopt other ways of transporting components and goods. Changing transportation means for semiconductor companies would be particularly costly, as it would require significant financial resources to adopt new environmental policies (Centobelli et al., 2017). Although a shift in supply chain management towards ecological sustainability is inevitable, it needs a more favorable economic climate than the current one for a smooth transition (von der Gracht & Darkow, 2016). New transport measures would also mean the need for a company to integrate into new transport infrastructure, which is also expensive (Kumar et al., 2017). It would also require additional human resources such as social media analytics to reorient supply chain channels (Choi et al., 2020). As one can see, changing means of transportation is a false alternative.

US-China Trade Relations: Regulatory Elements

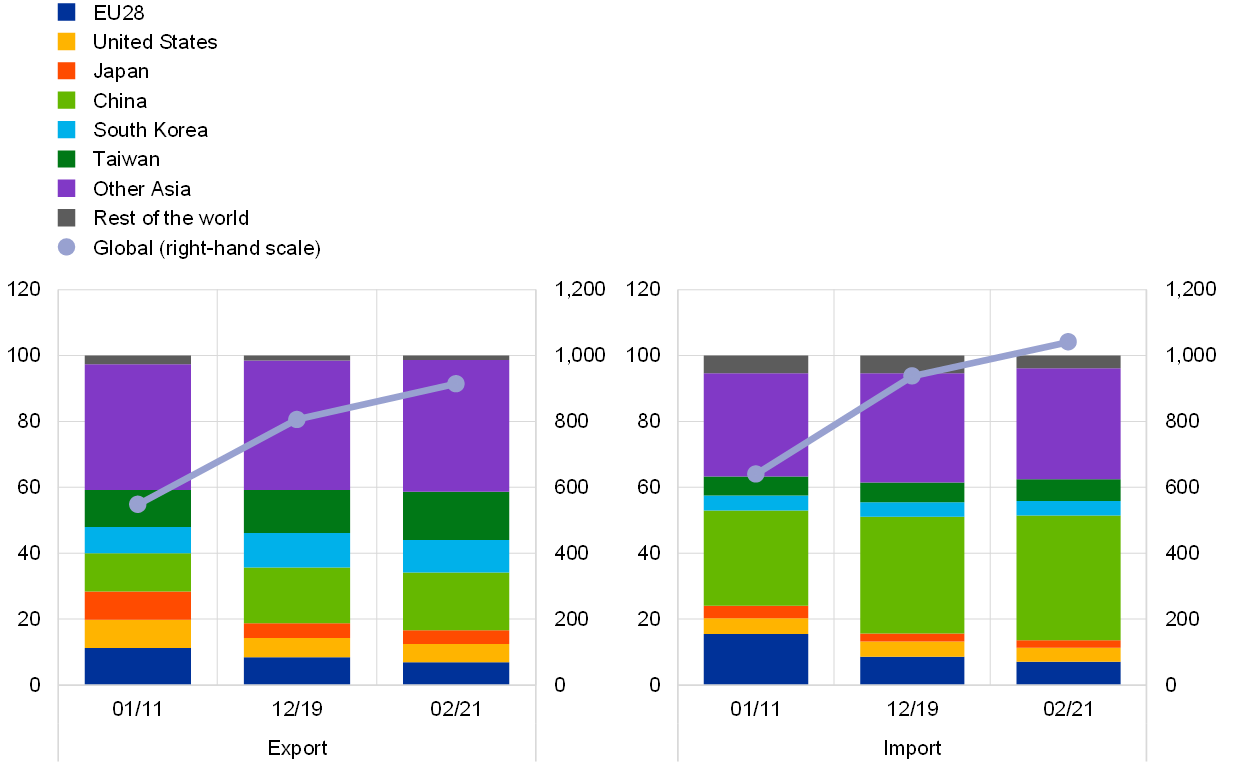

US-China trade relations is a highly important element to consider since it involves the two largest economies in the world, which have an intricate and complex relationship with each other. The given relationship can be categorized as a trade war, which was initiated in order to promote protectionism of the United States economy by the Trump administration (Yin & Hamilton, 2021). Figure 2 of the Appendix demonstrates the semiconductor trade share of China and the United States, which are significant (ECB, 2021). Evidence suggests that the current policies and associated tariffs, which constitute the trade war, are damaging to both parties. In other words, “a trade war is not a favorable position for any state to be in, but if a state must engage in protectionism, it should only do so if it can ensure that it can inflict greater asymmetric losses to the opposing state relative to its own losses from retaliatory protectionism and a loss of comparative advantage” (Yin & Hamilton, p. 15). Such a protectionist stance from the United States is driven by both economic and social priorities, which heavily impact the patterns of transportation, delivery, and supply chain. For instance, “the transport infrastructure is found to have a positive impact on jobs in the transportation and logistics clusters” (Kumar et al., 2017, p. 25). In other words, shortening delivery time approaches have to consider the trade relations between economies as well as associated cost increases and penalties.

New COVID-19 related government regulations regarding import-export semiconductors, especially from China, are the main reason for the increased delivery times in the United States industry. Moreover, it has also slowed down progress in such areas of supply chain management as transformational agility, flexible network integration, and global optimization (Speranza, 2018). Shortening and simplifying the logistics chain makes it much easier for business entities to comply with these new rules and obtain the necessary semiconductor components on time. In implementing strategies to shorten the supply chain, companies should focus their management improvement measures on the perfect order rate (POR). This approach allows companies to identify and highlight the most important goals and operations in their supply chain policy (Jacyna-Gołda et al., 2019). It is also noteworthy that the POR-centered approach also enables firms to optimize the different processes and procedures in their warehouses (Jacyna-Gołda et al., 2019). A precise knowledge of the central objectives and a clear understanding of acceptable operations allows businesses to comply with federal regulations accurately and avoid delays in the delivery chain.

Semiconductor Sector

The given analysis primarily focuses on the semiconductor sector and supply chain centered around the latter, which is why it is important to understand the underlying intricacies. It is stated that “the global model of semiconductor development has resulted in an asymmetric and interdependent relationship between China’s critical role in semiconductor production and those regions such as the US which control the key inputs into the value chain” (Grimes & Du, 2020, p. 1). In other words, China and its trade, as well as transportation, add a certain level of pressure on ensuring the overall supply chain resilience and efficiency when it comes to delivery. The main reason is that “the growing tensions between the US and China has created considerable uncertainty about the future evolution of this value chain” (Grimes & Du, 2020, p. 1). It is stated that more resilient supply chain networks can be designed by ensuring shorter delivery time through transformational agility and flexibility (Chester et al., 2021, p. 1). Therefore, the sector needs these measures in order to build more stable and efficient delivery patterns.

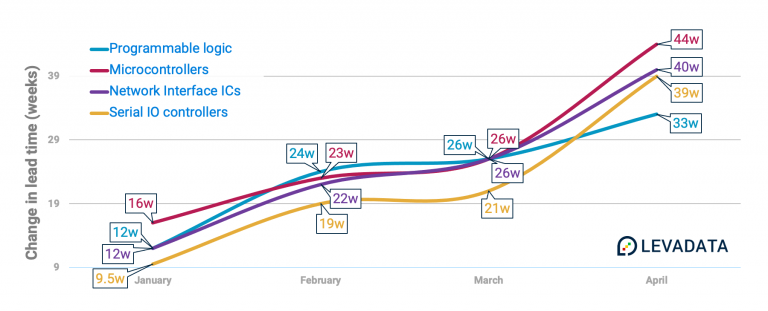

The semiconductor sector is especially interesting when it comes to supply chain management due to the exceeding shortage levels. Figure 1 of the Appendix shows how the lead times increased over the past year (Hruska, 2021). There are objective prerequisites between the United States and China that make up the initial foundation for the distribution of the logistics concept in the areas of production and circulation of enterprises entering into cooperative ties within the territorial production complexes, especially processing, transport enterprises, as well as enterprises performing transport forwarding and other logistics services. This fully applies to the semiconductor sector, which requires proper mediation in financial transactions between counterparties in the supply chain. Such prerequisites include the development of various production and technological facilities of industry, territorial and departmental systems for the supply and marketing of products, large automated transport and storage complexes, enterprises of various types of communications and transport, information dispatch centers, the latest computer and mobile network systems (Sakthivel et al., 2021). Using the accumulated world experience and the scientific and technical potential of enterprises, it is necessary to rapidly introduce modern logistics methods and systems at modern enterprises in various sectors of the economy.

Logistic support for transportation and storage of means and objects of labor is one of the most important functions of any enterprise and entrepreneur. In this regard, solving the problems of competitiveness of products involves the implementation of the principles of logistics at all levels of management in the relationship of planning, investment, and production in a single logistics cycle. According to the definition of logistics, the scope of its application in the organization and rationalization of commodity and related flows as they move from producer to consumer (Sakthivel et al., 2021). Logistics also includes management of purchases and stocks, production, marketing and transportation, personnel management, and information support of flow processes, including financial transactions in the supply chain.

Crisis and Supply Chain Management

Shortening the delivery chain by excluding the least significant participants is one of the best currently available tactics to reduce delivery times in the global regulations crisis caused by the COVID-19 pandemic. Kudláčková and Chocholáč note that “most companies are currently either directly or at least indirectly involved in a trading system that we call global” (Stopka, 2017, p. 00029). The widespread dangers posed by the COVID-19 pandemic have forced most countries, prominent industrial actors particularly, to develop and apply strict regulatory policies regarding their exports, imports, and travel. Their primary intention was to minimize the number of human interactions and, therefore, the infection rate. Unfortunately, these measures have caused significant damage to the global supply chain, especially those sectors where car and computer manufacturers operate, creating multiple significant and minor delays. Given the current external conditions, the best resolution for companies experiencing long delivery times is to shorten their delivery chain of semiconductors by excluding all its actors except one entity capable of providing large quantities of components and warehouses for them.

Restoration and maintenance of economic and organizational ties of enterprises complicated by the current economic crisis require active anti-crisis measures to implement exchange processes and bring manufactured products to the end consumer. As shown in Figure 3 of the Appendix, redesign through a delivery time shortening is necessary and appropriate under the current pandemic conditions (Messina et al., 2020). A necessary component of these processes is logistics, the main goal of which is to ensure the supply of the necessary products to the right place, at the right time, at optimal costs, of the required quality and quantity (Sakthivel et al., 2021). In the context of the globalization of the economy, the formation of a single economic space, logistics in most countries receives scientific and applied significance and development. The use of logistics as a tool for integrating enterprises and organizations into large supply chain networks and systems, which provide the possibility of optimizing end-to-end material flow using modern computer technology and communication technologies, can significantly reduce the time interval for the supply of goods and services from producer to consumer, contributes to a sharp reduction in unproductive use of material resources, accelerates the process of obtaining information and improving the level of service. The fundamental novelty of the logistics approach in the process of shortening the supply chain is to ensure an organic relationship between the links in the formation, promotion, sale of products and services, as well as end-to-end management of material and financial flows using the latest information technologies.

Planning has the main task of determining the volume of materials needed in a particular planning period. At the same time, a distinction is made between planning the requirements for materials, based on their consumption in previous periods, and the requirements due to the implementation of the production program. The main issue of each type of resource planning is the calculation of the volume of supplies distributed over time, at the place of consumption type, in such a way that leads to minimal costs for logistics operations associated with supplies. The organization of providing an enterprise with resources includes a set of tasks such as analysis, planning, control of processes occurring in this field of activity (Sakthivel et al., 2021). Supply chain managers of enterprises integrated into supply chains must make an informed decision. The latter is mainly about the system of organizing support, focusing on the relevant markets or direct economic relations with manufacturing enterprises. Decisions about what types of materials to buy in the markets or from cooperation partners and what quantity to focus on are important. In addition, it is necessary to determine aspects according to what criteria to choose suppliers, what types of transport to use for the delivery of materials equipment, and what storage methods to use.

Regulation of the supply chain management process, accompanied by financial and information flows, requires the integrated management of production, supply, and distribution as a single integrated system. The main task of such management is the optimization of all business processes while reducing logistics costs. The situation in the markets of material resources, which is developing in connection with the economic crisis, necessitates an increase in economic interest in the problem of resource management and the application of a logistics approach to the processes of supplying enterprises of various organizational and legal forms. The solution to this problem requires a theoretical study of the features of the manifestation of the law of supply and demand in the markets of raw materials, which, from the point of view of the logistics approach, should ensure a directed impact on minimizing costs throughout the supply chain and is a necessary condition for the competitiveness of an enterprise.

One of the most difficult modern conceptual problems of logistics in the entire process of creating a new and developing an existing enterprise is the search for sources of financing. The attraction of funds for financing can be made at the expense of internal and external sources. Investment activity is considered, in this case, as a process covering both investment and a set of practical actions for their implementation (Sakthivel et al., 2021). In this regard, there is a need for novel modifications of the interaction of logistics systems of enterprises of various organizational and legal forms with banks regarding the implementation of financial flows, since no other flow can be formed and moved to the consumer without the necessary financial resources.

Delivery Time Shortening

Delivery time shortening can be considered as the most viable and effective solution to the semiconductor supply chain issues under the current political, economic, and social pressures. When discussing supply chain management issues, many contemporary authors focus on the gaps that avert organizations from attaining high-quality logistics and manufacturing. For example, Centobelli et al. (2017) noted that the classification of green initiatives is one of the biggest gaps that yet have to be addressed by companies. This gap also includes a thorough evaluation of the performance of environmental sustainability, information, and mechanical technologies that support green initiatives. Such perspectives on supply chain management are crucial because they emphasize sustainability and the interconnectedness of businesses (Choi et al., 2020; Kumar et al., 2017). Many investigations on the topic rely on the benefits of social media and discuss the possible drawbacks of supply chain operations management that are affected by online instruments. Consistent with Choi et al. (2020), user privacy and data security are the two biggest gaps that cannot be ignored by supply chain actors. Thus, the emergence of new technologies represents a core benefit that cannot be utilized to realize the full potential of supply chain management initiatives.

The volume and nature of transport work are determined by the existing distribution of productive forces and the geography of communication routes, both on a national scale and in individual economic regions. Specializing in the production of certain types of products, economic regions feel the need to exchange various kinds of raw materials, fuel, semi-finished products, and finished products. In a planned economy, in order to determine the rational volumes of import and export of certain types of products, the relevant authorities compiled transport and economic balances, which were the starting documents for attaching suppliers to consumers and transportation plans. On the basis of these documents, matrices of cargo flows between cargo generating and cargo consuming regions were compiled for a certain planning period. In modern conditions of a market economy, the volumes of cargo flows between regions are set by regulatory documentation, and the laws of the market and their direction tend to maximize the satisfaction of the needs of the consumer of transport services. This situation complicates the process of assessing and, subsequently, forecasting future transport performance.

A deeper understanding of how supply chain operations could be mediated represents an essential contributor to the utilization of innovative technologies in addition to social media data parsing. Similar to Centobelli et al. (2017) and Choi et al. (2020), Gracht and Darkow (2016) reviewed the impact of technology on supply chain management and touched upon the notion of green initiatives. This topic is recurrently reinforced in the academic literature because it represents a long-standing concern intended to help companies mitigate the lack of sustainability. The fact that researchers take different scenarios and investigate the process of supply chain design shows that experience and cumulative knowledge are crucial for a better understanding of how to shorten the delivery chain while remaining in line with the corporate objectives and current supply chain principles (Gracht & Darkow, 2016; Speranza, 2018). Supply chains across the globe constantly go through adjustments that cannot be considered either unnecessary or minor, especially with technologies evolving on top of them.

Discussion: Recommendations and Ethical Aspects

The first recommendation that underlines the importance of shortening the delivery chain for manufacturers of semiconductors is the expansion of collaborative planning. The value chain has to be altered as well so as to provide manufacturers with an opportunity to attain larger reactions in supply and instigate the bullwhip effect (Stopka, 2017). The majority of cycle times are rather long, so any kind of disruption could be a devastating factor for semiconductor manufacturers. Irreversible cost implications cannot be ignored because planning has to be completed in a collaborative manner in order to maintain local supply chains as well. In accordance with Jacyna-Gołda et al. (2019), semiconductor manufacturing depends on demand-supply balance because of how the industry manages variations in collaborative planning among crucial stakeholders. This ultimately means that key value chain players affect semiconductor manufacturing and design to a certain extent because of the lack of stricter management. With this information in mind, more companies will be able to mediate their position in the market while protecting their image and products.

Another reason why shorter delivery chains could benefit semiconductor manufacturing is the existence of various suppliers that have to be managed by constructors. This approach is needed to gain continuous access to the ability to manage capacity risks and restructure the existing value chain (Centobelli et al., 2017). The increasing popularity of semiconductor manufacturing across the globe makes it crucial to shorten the value chain and remain consistent in terms of releasing new products continually. Consumers will also have a chance to explore innovative products and technologies and also provide feedback to improve manufacturers’ responsiveness and performance (Kumar et al., 2017). Supplier risk management has to be included in the list of essential practices because numerous similar strategies failed in the past due to inattentiveness and lack of effort. A detailed analysis of risks is going to become a shortcut for semiconductor manufacturers, as they will have the opportunity to predict market fluctuations. A foreseeable response to relevant changes in the industry is going to shorten the delivery chain in a natural way, allowing manufacturers to implement green initiatives without slowing down any of the existing processes.

From the point of view of supply chain management, another significant variable that has to be covered is manufacturing itself. Consistent with Gracht and Darkow (2016), optimization of business processes is also required. Currently, there are numerous new technologies that might become the future of semiconductor manufacturing (machine learning, artificial intelligence, etc.). The immense capital that had to be allocated to support semiconductor manufacturing in the past can be assigned differently. Even the smallest disruptions could affect the industry in an irreversible manner, so manufacturers have to keep up with the technological progress and ensure that schedule delays are eradicated (Stopka, 2017). Capacity utilization is going to be optimized and improved together with manufacturing resilience, creating room for innovative manufacturing methodologies. This means that the majority of industry moguls can become unreachable by simply altering their supply chains in response to the changes that have occurred over the past two years due to the Covid-19 pandemic (Choi et al., 2020). Not all companies have the opportunities and resources to respond to such drastic transformations in a timely manner.

A thoughtful review of logistics and transportation concepts could become the key to measuring essential supply chain attributes and introducing respective changes. Even though the job itself remains the primary focus for many organizations, a shortened delivery chain can be best developed and deployed within an environment where supply chains are capable of such activities (Kumar et al., 2017). Thus, supply chain management should focus on supporting the transportation infrastructure and ensuring that all areas are reachable. The introduction of new strategies and efforts should be justified by the question of specialization, where logistics employees would be required to expand their knowledge on manufacturing and delivery. That would become their opportunity to contribute to organizational success during brainstorming sessions and the implementation of new supply chain management strategies (Speranza, 2018). By doing this, employees can gain more experience while only resorting to evidence-based solutions. Therefore, a shortened delivery chain could be a consequence of a streak of operational management decisions aimed at implementing new logistics solutions.

Semiconductor manufacturing relies heavily on operational research and the effectiveness of approaches to logistics. Hence, the key priority for many researchers in the area is to ensure that the existing decision-making processes can be supported by technology (Kumar et al., 2017). This would help supply chain managers achieve a higher grade of sustainability while ensuring that reasonable operational research can be conducted with the available entry data. This also means that the current developments in the area hint at the need to review supply chain management strategies more often. The semiconductor industry might benefit from shortened delivery chains because of the increased efficiency of the given transportation system (Choi et al., 2020). Knowing that technological evolution is practically unstoppable, researchers have to consider new ways of improving delivery chains and creating room for stronger management and economy. Green initiatives supported by Centobelli et al. (2017) have to be prioritized as well if the industry expects to attract more followers and create supply chains that save time and money without affecting the environment. Hence, sustainability is the cornerstone of altering delivery chains and developing a stronger organizational supply network.

One more problem that can be resolved with the help of shortened delivery chains is the introduction of changes into the current product platform. The inherent flexibility could be an essential way for semiconductor manufacturers to align their processes against a completely new framework (Choi et al., 2020). The industry responds positively to such changes because numerous manufacturers are keen on developing their unique platforms instead of working collaboratively on launching a unified platform. With consumer demands becoming exceptionally complex nowadays, it can be harder for semiconductor manufacturers to adhere to preset strategies in the long run (Speranza, 2018). Shared technologies are going to expand horizons for semiconductor manufacturers, but only in the case where they simplify their processes and reduce development cycles. In this case, a shortened delivery chain is going to become an exclusive advantage possessed by organizations where management units prepared themselves for challenges revolving around innovations. Technology should never be underestimated, especially when new developments tend to create additional rewards for the ones using them.

The ultimate objective to meet is to ensure that transportation options are carefully reviewed and altered to reflect the needs of the given manufacturer. From logistic planning to the execution of the product development strategy, constructors have to pay attention to the supply chain and its dispersion grade (Centobelli et al., 2017). In other words, transportation is one of the unique variables that control supply chain management and affect lead times and project phases. Every other generation of semiconductors requires a much more flexible and exquisite approach to transportation so that unwanted damages could become a crucial problem for manufacturers (Gracht & Darkow, 2016). In order to avoid this issue in the future, a shortened delivery chain should be implemented to optimize the cost of logistics and capture the required industry growth. It can be recommended to focus on planning initiatives more often in order to make sure that semiconductor manufacturing is a premeditated process that can be altered on the fly.

Conclusion

In conclusion, shortening the delivery chain is the best possible solution for many manufacturers of semiconductors because of the consistent growth that the industry sees, even in the light of the COVID-19 pandemic. The existing evidence shows that the growth is going to continue relentlessly, improving organizational incomes and reducing numerous corporate risks experienced by manufacturers. The increasing demand paves the way for additional challenges that have to be resolved by semiconductor manufacturers with the aid of hardware and software solutions that improve production lines. The possibility of skipping some of the crucial problems from the past increases the chances of manufacturers to shorten the delivery chain and ensure that the supply-demand balance is preserved. The market cycle has continued to evolve over the course of the past two decades, making it harder to develop a viable product platform and develop essential partnerships. Semiconductor manufacturing requires new trade policies and actions that will be taken to shift the market and make the best use of the available opportunities.

Based on the evidence acquired within the framework of the current paper, it may be concluded that the semiconductor industry can still be described as rather unstable due to natural disasters and geopolitical relations taking a toll on both companies and consumers. These challenges could have an irreversible influence on semiconductor manufacturing supply chains and their responsiveness to global market alterations. The future improvements depend on numerous factors, such as production planning and relationships with suppliers, where the true potential of the majority of manufacturers is yet to be discovered.

The trend of constructors becoming more and more independent also reflects the need to address transportation requirements and make necessary changes to product platforms. This would lead to the creation of regional manufacturing hubs where the given delivery chain will be reduced to a reasonable minimum. In the nearest future, semiconductor manufacturers are going to be required to address their procurement workflows and communicate with consumers more often. In modern conditions of expanding international trade relations, the development of world transport markets, the practice of relocating production and introducing methods of doing transnational business, the role of regions, namely, their transport subsystems, as separate elements of global transport corridors and trade routes is increasing. From this point of view, the assessment of the transport subsystem of the region as a set of organizations and enterprises moving towards a common goal, being in a state of competition with other transport subsystems, becomes important.

Appendix

Note. Lead times for semiconductors drastically increased thrice over four months.

Note. Both US and China constitute to a quarter for export, and China is the major importer.

Note. Redesign through a delivery time shortening can increase resilience and adhere to current regulatory pressures.

References

Centobelli, P., Cerchione, R., & Esposito, E. (2017). Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions. Transportation Research Part D: Transport and Environment, 53, 454-470. Web.

Chester, M., El Asmar, M., Hayes, S., & Desha, C. (2021). Post-disaster infrastructure delivery for resilience. Sustainability, 13(6), 1-18. Web.

Choi, T. M., Guo, S., & Luo, S. (2020). When blockchain meets social-media: Will the result benefit social media analytics for supply chain operations management? Transportation Research Part E: Logistics and Transportation Review, 135, 1-11. Web.

ECB. (2021). The semiconductor shortage and its implication for euro area trade, production and prices. European Central Bank. Web.

Gracht, H. A., & Darkow, I. L. (2016). Energy-constrained and low-carbon scenarios for the transportation and logistics industry. The International Journal of Logistics Management, 27(1), 142-166. Web.

Grimes, S., & Du, D. (2020). China’s emerging role in the global semiconductor value chain. Telecommunications Policy, 1, 1-14. Web.

Hruska, J. (2021). Semiconductor shortage enters ‘danger zone’ as lead times rise. Extreme Tech. Web.

Jacyna-Gołda, I., Kłodawski, M., Lewczuk, K., Łajszczak, M., Chojnacki, T., & Siedlecka-Wójcikowska, T. (2019). Elements of perfect order rate research in logistics chains. Archives of Transport, 49(1), 25-35. Web.

Kudláčková, N., & Chocholáč, J. (2017). Warehouse location problem in context of delivery time shortening. In MATEC Web of Conferences. Vol. 134 (2017): 18th International Scientific Conference-LOGI 2017. EDP Sciences. Web.

Kumar, I., Zhalnin, A., Kim, A., & Beaulieu, L. J. (2017). Transportation and logistics cluster competitive advantages in the U.S. regions: A cross-sectional and spatio-temporal analysis. Research in Transportation Economics, 61, 25-36. Web.

Messina, D., Barros, A. C., Soares, A. L., & Matopoulos, A. (2020). An information management approach for supply chain disruption recovery. The International Journal of Logistics Management, 31(3), 489-519. Web.

Sakthivel, A. R., Kandasamy, J., & Davim, J. P. (2021). Managing supply chain risk and disruptions: Post COVID-19. Springer.

Speranza, G. (2018). Trends in transportation and logistics. European Journal of Operational Research, 264(1), 830-836. Web.

Stopka, O. (2017). 18th international scientific conference – LOGI 2017. EDP Sciences.

Yin, J. Z., & Hamilton, M. H. (2021). The conundrum of US-China Trade relations through game theory modelling. Current Politics and Economics of Northern and Western Asia, 30(1), 87-93. Web.